YW Quality

Quality is a cornerstone of Yonwoo’s identity. Constant refinement of the quality management system results in better value to customers by providing unrivaled products and services that meet or exceed needs and expectations.

With a priority of customer satisfaction, improvements are made on the manufacturing environment and equipment based on strict quality control and optimized quality management systems.

Skilled quality experts monitor the entire process from product development through customer delivery. Quality issues can be discovered and remedied at any point in the process.

Every process such as design, production, and post production is managed through the Quality Management System (YQMS). Throughout the process, each inspection stage is measured by advanced equipment and thoroughly analyzed.

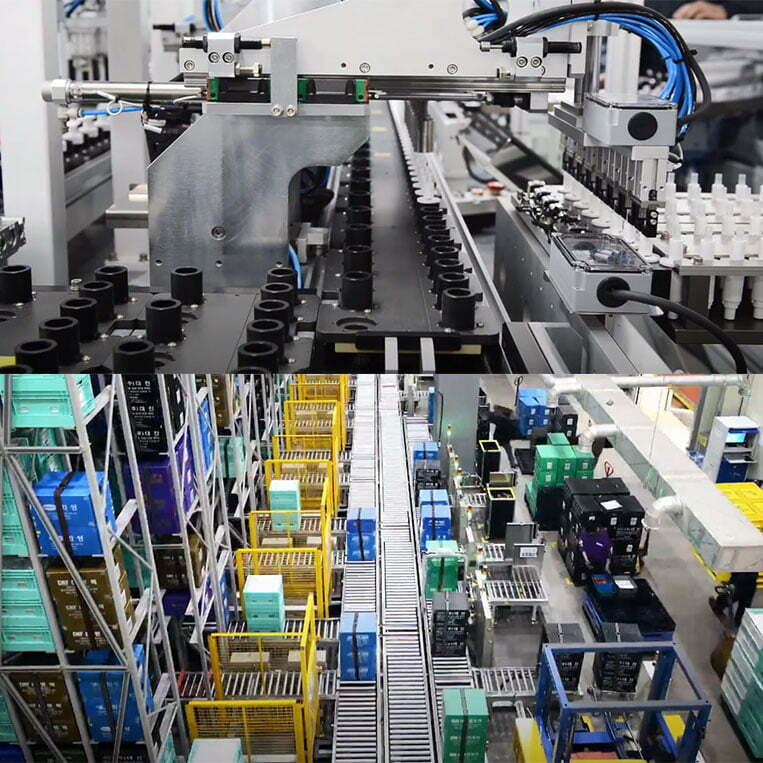

Materials, and finished products, are conducted through an unmanned smart material system, the foundation of the smart factories. Customer jobs are loaded and operated first-in / first-out on available smart factories.

Quality Across Processes

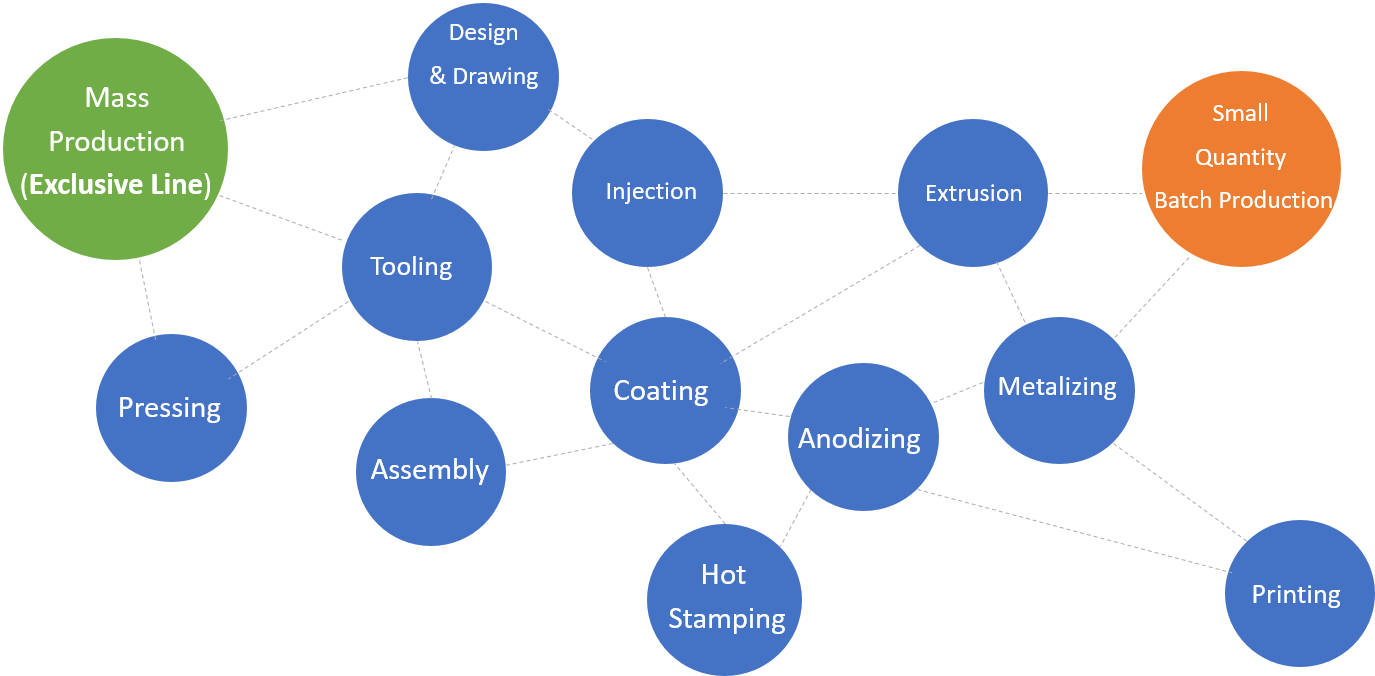

To meet customer needs, Yonwoo has developed extensive in-house production capabilities. Beyond being able to cater to every customer, the in-house system enables them to monitor quality across every step, from development to delivery.

Specialized Processing System

- Yonwoo is very proud of their reputation for the best quality in the industry.

- Yonwoo uses only top grade raw materials. Each process, from tool making to injection molding to coating to vacuum metalizing, printing and assembly is systematically monitored by expert technicians to ensure products that customers can trust.

- Automated smart factories for unmanned processing.

- Technicians must access manufacturing floors via clean rooms to avoid contamination and ensure quality.

- “QUALITY FIRST” is the mantra across all processes.

IN-HOUSE SYSTEM

YONWOO QUALITY MANAGEMENT SYSTEM

YQMS

Real-time quality status, quality indicators, quality index and quality improvement metrics.

Advanced product quality planning by validating improvement activities and baselining standard applications.

YONWOO QUALITY MANAGEMENT SYSTEM

Integrates distributed quality information sources for enterprise-wide sharing: quality skills and know how, improving records, as well as prevention of recurrence.

Accelerates quality improvement process: immediately raises quality issues for real-time tactical process improvements until long-term measures can be deployed.

Mitigate the effects of manual quality management by providing real-time analysis and sharing related quality improvement cases.

Quality monitoring visualization and feedback: presents quality issues (with associated classification and improvements), checks each verification stage in real time, and provides feedback for filing quality improvements.

Real-time quality status, quality indicators, quality index and quality improvement metrics.

Advanced product quality planning by validating improvement activities and baselining standard applications.

QUALITY ENVIRONMENTAL POLICY

Continually improve processes to satisfy customers, suppliers, and partners in accordance to ISO 9001, ISO 15378, and ISO 14001.

Conducting regular reviews against quantitative objectives based on relevant laws as well as other requirements and best practices.

Strengthening the relationships between suppliers, customers and employees to facilitate communication and preventing quality and environmental problems.

QUALITY MANAGEMENT POLICY DEPARTMENT

Proactive Quality Control

Quality Control Per Gate

Satisfying the needs of domestic and international customers

Direct the quality management process by focusing on the the customer’s perspective and needs, consequently contributing to customer satisfaction and corporate sales.

Promote innovative quality improvements, across enterprise organizations and cooperative companies, based on analysis of collected data.